1900

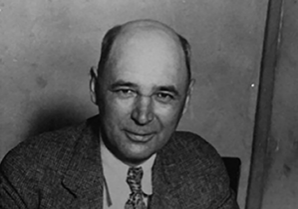

Edward Stanek Sr. graduates from the University of Prague in Czechoslovakia and emigrates to the United States.

1924

Stanek Tool is founded at N. 28th Street & North Avenue in Milwaukee, WI.

1926

Stanek Tool location moved to 2558 N. 30th Street in Milwaukee, WI.

1941

Stanek Tool moved to it’s third location at 29th & Vliet Street in Milwaukee, WI.

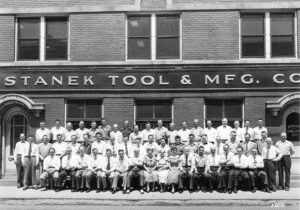

1956

2nd generation leadership at Stanek Tool begins with Jerome, later Edward Jr, and finally Thomas in 1985.

1972

Current facility built in New Berlin, WI.

1994

3rd generation leadership at Stanek Tool begins with Mary Stanek- Wehrheim.

2016

Stanek Tool’s senior leadership team invests in the business alongside Milwaukee based Jacsten Holdings.